One of the Hong Kong government’s early pilots of the NEC contract suite was for improving the interchange between Yuen Long Highway (part of Route 9) and Castle Peak Road next to Pok Oi hospital. Despite proving to be a particularly difficult project, the project team was able to maintain a collaborative working relationship throughout.

The Highways Department (HyD) initially let the work to contractor Build King Civil Engineering in November 2012 under a HK$170 million (£17 million) NEC3 Engineering and Construction Contract Option C (target contract with activity schedule). Mott MacDonald was appointed to perform a dual role as HyD’s external NEC advisor and financial consultant.

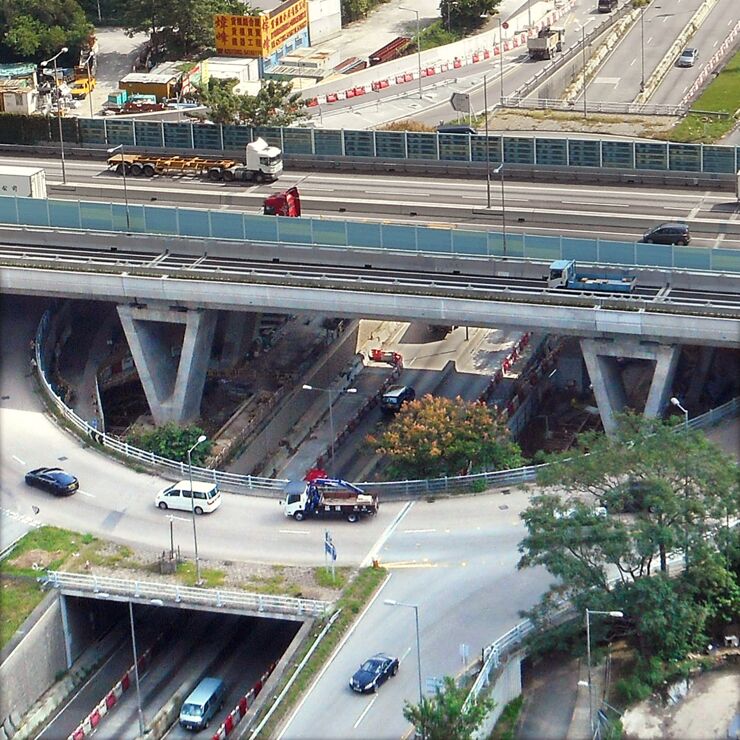

The project involved designing and building an additional elevated northbound lane on the west side of the existing Route 9 flyover, new northbound and southbound slip roads on the south side of the junction, wider northbound and southbound slip roads on the north side of the junction, and a dedicated left-turn lane off the southbound carriageway for Au Tau traffic.

The works were complicated by being carried out directly over and next to fast-moving traffic in a congested urban environment. This and various unforeseen ground problems, including the discovery of a major utility under the proposed flyover pier foundations, ultimately led to the completion date moving from August 2015 to October 2016 and the budget eventually being exceeded.

One team, one goal

Project manager delegate Daniel Chow recalls, ‘The local construction industry was generally unfamiliar with NEC partnering approach at the time when the contract started. The project team members realised at an early stage that it was essential for them to build trust with one another so as to achieve true co-operation and collaboration.’

He says one of the key differences from traditional contracting was the duty by both the project manager and contractor to raise early warnings for identified risks and then participate in risk reduction meetings to mitigate or even pre-empt the risks. ‘The project manager had to act as a custodian of the price for works done to date as well as the total of the prices. The conventional attitude of solving the site problems by identifying “our or their responsibility” was changed to working collaboratively under a one-team identity.

‘The project manager and contractor also had to communicate properly to ensure full transparency of the rationale and assumptions behind each submitted programme before it could be accepted for use in the contract. In addition, the use of defined cost in assessing payments and compensation events also required the project manager and contractor to work together to establish the requisite transparency to the contractor’s accounting system to enable proper assessment of defined cost with the required confidentiality suitably maintained.’

Inspired by the NEC obligation to act in a ‘spirit of mutual trust and co-operation’, the senior management of HyD and the contractor agreed to establish a ‘one team, one goal’ concept. ‘Both parties jointly participated in a series of start-up training workshops to gain the technical knowledge and soft skills needed for administering the contract. With the full support from senior management and NEC training, a strong sense of mutual trust and one-team mentality was gradually developed.’

Managing pain share

However, just when the project team started to enjoy their collaborative working relationship, the contractor gave notice that the contract would potentially be in a ‘pain’ scenario as revealed from monthly financial forecasts. ‘Similar to some other ECC target cost contracts, core clause 53 had been amended to allow downward adjustment of the amount due to the contractor’s pain share based on the project manager’s interim assessment of the contractor’s share on a monthly basis,’ says Chow.

‘Given the contractor’s cash flow would be reduced under a pain scenario, a further review was jointly conducted by the project team before the project manager and contractor eventually agreed on how to make the best of the pain journey, maintaining team members’ morale and the one team, one goal mindset.’

Despite the client’s commitment to the contractor’s pain share being capped at 5% of the total of the prices, HyD stepped up efforts to work with the contractor to reduce its pain as much as practicable. ‘Close communications between HyD management and the contractor led to a mutual agreement on further strengthening the budget control. Thanks to the NEC provisions, a number of measures to enhance cost effectiveness were also implemented under the contract,’ says Chow.

Mitigating risks and costs

According to Chow there were a total of 18 early warnings notified by the contractor and project manager, 17 of which were dealt with during the contract period (the remaining early warning was a claim from a subcontractor as the subcontractor was unwilling to withdraw the claim until its subcontract was settled). ‘We started holding risk reduction meetings every month – 29 in total − to strengthen collaborative risk management and to ensure more proactive risk identification, followed by timely mitigation to minimise adverse impact on time, cost and quality to the contract’

He says the project team tackled a number of unexpected risks due to uncharted utilities. ‘For example, the flyover pier piles were found to conflict with a serving utility 8 m below ground. Given this was a main supply to Yuen Long town, the team worked with the utility company during a series of risk reduction meetings to consider the cost and time implications of various possible solutions, and eventually agreed on the most cost-effective option for implementation. The utility company was also continued to be invited to attend the risk reduction meetings so that the team could closely monitor the progress of works and provide immediate assistance during the works for the delay mitigation.’

Post-tender interviews with tenderers for each of the 30+ subcontracts were also conducted as far as practicable. ‘This substantially reduced the potential for disputes and enabled the project manager to review the contract design to see if any cost-effective alterations could still be made before the subcontract award,’ says Chow. ‘For instance, following the advice from potential subcontractors, we adjusted the width of a new slip road and hence the alignment of the roadside retaining wall. This minimised the disruption to the original retaining wall, significantly reducing the extent of works required.’

Streamlining procedures

Chow says regular partnering review meetings were held between key project management staff to monitor partnering within the project team and promote the ‘hand-in-glove’ working environment. ‘The latest developments in communications technology were adopted, including creating a number of WhatsApp groups to monitor progress and exchange ideas for solving site issues in a more efficient manner.’

He says an alternative approach to dealing with compensation events through unlocking innovation was also encouraged under ECC clause 62.1 via proactive discussions between the project manager and contractor. ‘The aim was to explore all possible measures and actions that could be taken to enhance the cost-effectiveness for the works affected by the compensation events.’

In addition, stringent reviews on forecast defined cost for providing the works were held regularly between the project manager and contractor. This included reviewing contractor’s staff deployment, procurement of subcontracts, plant, materials and equipment, stock management and material wastage to look for cost savings without compromising contract requirements.

‘Overall, the cost-saving measures implemented on the contract reduced the extent of the pain for both parties, enabling the contract to be satisfactorily completed in October 2016,’ says Chow. ‘Continued use of NEC principles during the pain scenario helped the parties mitigate further risks and unlock all possible cost-saving measures. The pain journey on this project would have been far more difficult under a conventional contract regime.’

Benefits of using NEC

- NEC target cost contract encourages transparency and provides a fair allocation of risk between client and contractor.

- NEC obligation to work in a ‘spirit of mutual trust and co-operation’ encourages parties to collaborate throughout the works, even under a ‘pain’ scenario, so that they continue to seek the best possible outcome for the project.

- NEC early warning and risk mitigation process ensures potential risks are identified from the outset, ensuring minimum possible impact on budget and programme.