The Environment Agency has used NEC contracts to procure a vital new coastal flood defence in eastern England. The £28 million tidal barrier in Ipswich, Suffolk will help protect 2,000 properties from North Sea storm surges.

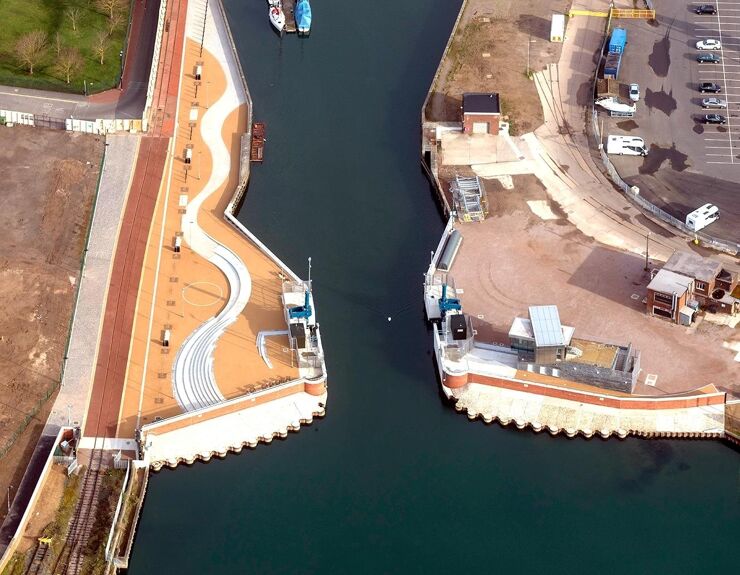

The 22m wide, 9m high, 200t rotating radial-sector gate across the mouth of the New Cut on the River Orwell is the final element of a £67 million programme to provide 1 in 300-year flood protection for 1600 homes and 400 businesses over the next 100 years. It also serves as a replacement for an existing flow control structure at the site.

The barrier works included a main control building, a 9m wide mitre floodgate across the adjacent railway line, various other floodgates and walls connecting the new barrier to the previously completed east and west bank works, a public amenity area, a hard landscaped area, seating and a viewing platform on the west bank.

The Environment Agency let the barrier works to VBA, a joint venture of Volker Stevin, Boskalis Westminster and Atkins, under an NEC3 Engineering and Construction Contract (ECC) Option C (target contract with activity schedule) in November 2014. Arcadis and Jacobs were appointed ECC Project Manager and Supervisor respectively under NEC3 Professional Services Contracts (PSC).

The barrier works were completed in February 2019 and received an Institution of Civil Engineers’ Exceptional Merit Award for technical excellence and innovation in October 2019.

Flexibility and collaboration

Environment Agency project manager Andrew Usborne stated that NEC contracts were chosen because of their flexibility and an approach that engenders a fully collaborative working relationship. ‘Collaborative working was encouraged from the outset of the contract. In particular, NEC early warnings were encouraged as a positive tool to flush out issues proactively at regular risk-reduction meetings.’

To ensure all team members understood the requirements of the contract and to reduce the risk of commercial disputes, Usborne says an NEC contract administration workshop was held at the outset. ‘We also held regular commercial meetings throughout the project to track changes and ensure prompt action.’

He says the contractor was fully incentivised to find savings and avoid delays through NEC’s cost-sharing mechanism. ‘The pain/gain share model was set at 85% maximum gain and 115% maximum pain in comparison to defined costs. Between 85% and 115%, gain and pain were shared 50/50, with defined costs capped at 115% of the target.’

Following a fundamental review of gate geometry and function, redesign of piled foundations and a drive to minimise waste off site, VBA was able to cut steel volumes by 30%, avoid 350 lorry movements and save nearly £2 million in costs. There were also no reportable accidents in more than 300,000 man-hours worked.

Benefits of using NEC

- Plain English contract wording of NEC encouraged all parties to refer to the contract as needed.

- NEC requirement for robust programme updates throughout the project enabled progress to be accurately tracked.

- NEC early warning process ensured pro-active resolution of problems as they occurred rather than being left until ‘final account’ as per other contract forms.